India’s Arjun Main Battle Tank has had a checkered production history. Among its litany of woes is the latest missive from Germany’s MTU, which could delay the production of its engines by four years. However, the delay could be the opportunity to indigenize the tank’s engine.

India’s Arjun Main Battle Tank has taken more than its share of hits. It could arguably be labeled the nation’s most protracted and arduous arms endeavor.

Hobbled as it is by delays, the latest salvo has come from Germany: it has signaled a delay of around four years in providing the vital engines needed for the Arjun Mark 1A tank—result: a dark shadow over the MBT program’s progress.

In 2021, India placed an order worth INR 7,523 crore ($900 million) for 118 Arjun Mark 1-A Main Battle Tanks (MBTs), often referred to as ‘Hunter Killers.’

The Arjun Mk-1A is an enhanced iteration of the Arjun Mk-1 main battle tank, which is presently in active service with the army. The Arjun Mark 1-A, representing a significant technological leap from its predecessor, the Mark-1, features a higher indigenous component, boasting new advancements such as a powerful 120mm rifled gun and Kanchan armor for enhanced firepower and protection.

These powerful machines are manufactured by the state-owned Heavy Vehicles Factory in Avadi, Chennai. However, the timely delivery of these tanks is currently in jeopardy due to a shortfall in engine availability.

The tanks were originally designed to be equipped with engines sourced from a German firm. The company has indicated a significant delay in fulfilling the order, posing challenges to the scheduled deliveries.

ANI, citing sources, recently reported that German engine manufacturers have stipulated a requirement of approximately 48 months to restart the production of engines destined for the Arjun Mark 1A tanks.

Some existing engines, however, are already in possession of the development agencies, and these will be utilized to manufacture the initial batch of tanks for the Defence Ministry’s order of 118 tanks.

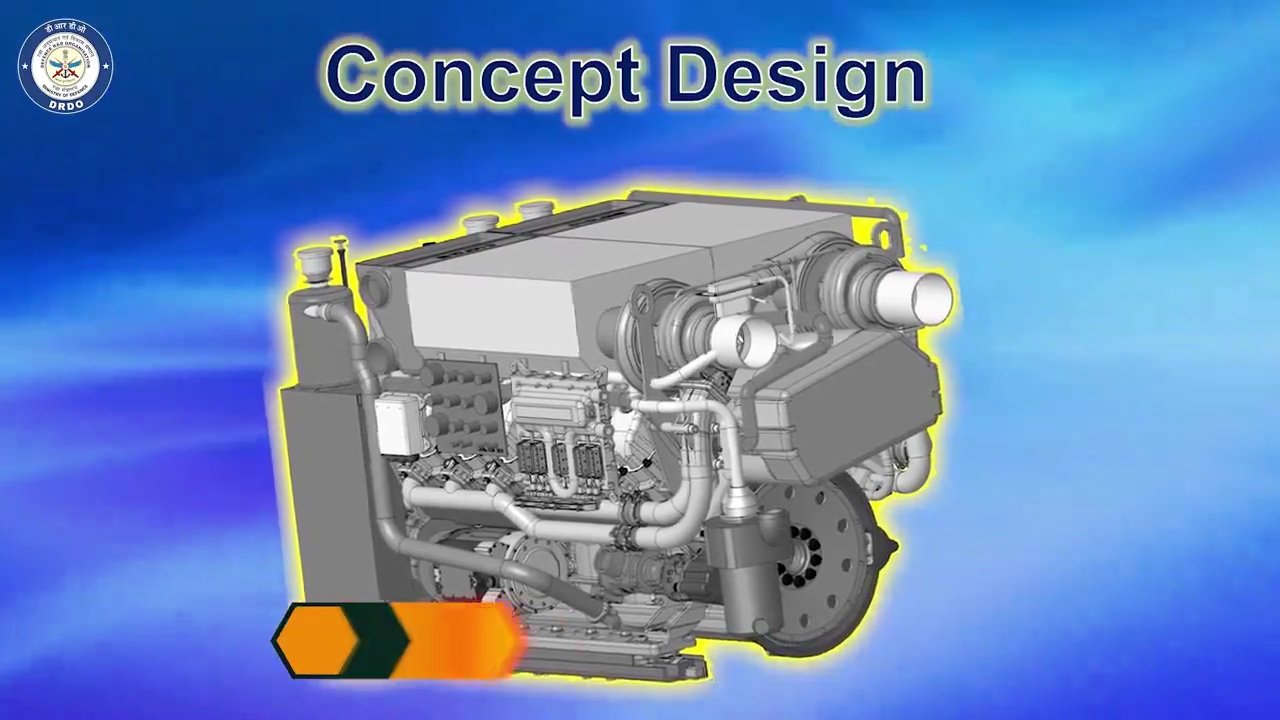

Meanwhile, with the project facing delays, the involved agencies are seizing the opportunity to utilize the time to craft an indigenous engine suitable for powering the Arjun Mark 1A tanks.

According to the Economic Times, the Defence Research and Development Organization (DRDO), the premier agency under the country’s Ministry of Defense, has embarked on a project to develop an indigenous solution that is expected to be ready for production within three years.

The DATRAN 1500 engine, initially conceptualized for the Futuristic Main Battle Tank program, is presently undergoing adjustments for seamless integration into the forthcoming Arjun Tanks. The new engine completed its inaugural testing phase as part of the future tank program last year.

Causes For Germany’s Delay In Engine Supply

Germany’s inability to supply engines to India is not a novel occurrence. It mirrored a past setback for New Delhi when the German government withheld BAFA (Federal Office for Economic Affairs and Export Control) clearance for engine exports to India, impacting the indigenous Zorawar light tank prototype.

Consequently, India was compelled to turn to American company Cummins for tank engines in October 2023. At that time, Germany had not provided specific clarification on the reasons behind the decision to withhold the supply of tank engines to India.

Germany maintains stringent regulations governing arms exports, with a particular focus on considerations such as human rights, regional stability, and conflict zones. These regulations may occasionally impose restrictions or delay arms sales to countries like India, influenced by the prevailing political and security conditions at the time.

However, concerning the delay in furnishing engines for India’s Arjun tanks, experts conveyed to EurAsian Times that there could be various additional explanations, including the limited quantity of ordered units, considerations regarding economies of scale, and Germany’s internal industrial challenges.

When questioned about the potential factors behind Germany’s challenge in resuming engine production for India on time, Lt. Gen AB Shivane, former Strike Corps Commander and Director General Mechanised Forces, suggested that the “limited quantity” of orders could be a major factor contributing to the prolonged timeline for restarting the production line.

Speaking to EurAsian Times, Rahul Manohar Yelwe, a Senior Research Fellow at the Center for Security Studies, explained that reviving the engine production line would necessitate the German company MTU to reestablish the entire supply chain intricately linked to the project, a process that inherently consumes a considerable amount of time.

He elaborated on another rationale, highlighting that Germany has a limited tank inventory, unlike the United States, Russia, and India, which boast a substantial number of tanks in their fleets. This implies a lower domestic demand, and thus, if a specific engine lacks orders, it makes little sense to sustain the production line for that particular power plant.

Hence, the delay in Germany’s ability to supply engines for Arjun Mark 1 tanks can be comprehended, given that the company would need to orchestrate an entire supply chain. This process may entail numerous challenges, including the identification of new vendors and the negotiation of new agreements with other subcontractors.

Obstacles In Crafting An Indigenous Engine

The instances of Germany’s inability to supply engines on schedule could serve as a catalyst for New Delhi’s current endeavors to enhance its indigenous engine capabilities.

As stated, New Delhi is now pursuing the creation of an indigenous engine for the Arjun tank. Yet, this ambitious endeavor is bound to present a series of challenges that the development team must navigate and conquer along the way.

One major question arising from this situation is whether the shift toward a new engine will entail any potential delays in the overall delivery timeline and setbacks for the Arjun tank program as a whole.

Rahul Manohar Yelwe explained that the design of the Arjun tank was originally centered around the German engine. The introduction of a new engine implies that design modifications may be required to integrate it into the tank.

Subsequently, both the engine and the tank will undergo a comprehensive series of separate and simultaneous tests and trials to assess whether the new engine effectively meets all the required parameters.

This sequence of events, in turn, is likely to extend the overall delivery timeframe. By the time this entire process concludes, there is a possibility that the need for a new tank may arise, potentially to replace the existing T-90 and T-72 models, according to the Yelwe.

Meanwhile, Lt. Gen. AB Shivane mentioned that India possesses the necessary capabilities to develop a homegrown engine. However, he questions whether it will be economically viable compared to investing in a fleet of medium and light tanks currently under development.

Nonetheless, the country is also focusing on acquiring capabilities to maintain the existing German engines, aiming to decrease dependence on MTU and improve the availability times for the Arjun tank.

India’s Engine Factory Avadi recently announced the commencement of in-house repairs for Arjun Tank Engines, achieving successful completion.

The inaugural run of the repaired engine was overseen by Dr. Kamat, Secretary of the Department of Defence Research and Development (R&D) and Chairman of the Defence Research and Development Organisation (DRDO).

The factory said, “After trials, this project would be a huge success towards the journey of indigenization and make in India mission.”

Operational Hurdles With the Arjun Tank

The Indian Army primarily relies on Russian tanks, with approximately 1,900 license-built T-72M1s and around 1,500 T-90Ss in its inventory. These T-90Ss are third-generation Russian main battle tanks developed as successors to the T-72.

On the other hand, India’s homegrown Arjun was envisioned to replace the Soviet-built T-72 tanks with several capabilities surpassing those of the Russian tanks.

During a friendly duel with the T-90 tanks in 2008-2009, the Arjun Main Battle Tank (MBT) demonstrated superior performance compared to the Russian system across various parameters, including firing accuracy and stability.

Despite its superior capabilities, the primary drawback of the tank lies in its weight. Originally designed to weigh only 48 tons, the Arjun tank exceeded expectations, ultimately reaching a weight of 62 tons. Its latest iteration now tips the scales at 68.5 tons.

Lt. Gen AB Shivane said, “Arjun Mk1A or Arjun Mk2 have weight penalties which are not optimal for our operational requirement.” The weight of the Arjun has also been generally cited as a factor that has dissuaded the Indian Army from ordering more units, as it is incompatible with the infrastructure in the Western sector.

Rahul Manohar Yelwe stated that the development and procurement of a tank revolve around three main points: firepower, protection, and mobility. He further explained that the design of the Arjun tank is based on the Leopard 2A4 tank, following the Western design philosophy.

In contrast to Russian tank design, where firepower and mobility play a crucial role, Western tanks are largely inclined towards prioritizing better protection and firepower.

To enhance the Arjun tank’s protection, it is equipped with the locally designed composite blend Kanchan armor. This armor provides the tank with better protection, but it comes at the expense of increased weight, leading to a reduction in tactical and operational mobility.

However, he stressed that placing all the blame solely on the Defence Research Development Organisation (DRDO) was not fair.

In contrast to the Indian Navy, which has an in-house Directorate of Naval Design collaborating closely with development agencies right from the outset to design weapon systems, the Indian Army lacks such an agency.

Consequently, as the project advances, the Army often finds itself wanting to incorporate additional features into the tank, such as larger guns and improved armor, which can present challenges in implementing changes.

Nonetheless, Yelwe added that the weight concern presents a notable obstacle, given that many bridges along the border were primarily designed and constructed to accommodate Russian tanks.

Moreover, transporting the Arjun MK 1A by train is difficult as it requires dedicated Mobile Bogie Well Wagons. The Indian logistics system is optimized for medium-weight tanks, making it challenging to create a separate network for just four regiments of the Arjun MBT, primarily designed for desert theaters.

- Contact the author at ashishmichel(at)gmail.com

- Follow EurAsian Times on Google News